Development Firearms & Equipment

After initial work on the cartridges had reached a point where chambering reamers could be ordered, it was time to firm up testing scheme. I felt that the 4 distinct Phases were necessary. The first was to confirm that the cartridges, as designed, would function, fire form, and reload as anticipated. Phase two would concentrate on basic load development. The goal of this testing was (and is) to establish acceptable velocity and pressure parameters for pairs of powders and bullets. Since there are literally thousands of powder types, charge weights, and bullet weights and configurations, this is an ongoing project which will probably not be completed a considerable amount of time. For this reason, much time has been and will be spent with the QuickLOAD internal ballistics program to “pre-qualify” potential combinations before they are committed to shell, powder, and bullet. Phase three is the development of the most desirable loads within the envelops defined in Phase two. Desirability is defined as finest accuracy, and highest velocity possible while staying within moderate pressures. By design, best accuracy will always take precedence over highest velocity – it doesn’t matter how fast the bullet gets there if it doesn’t hit the target. Phase 4 is actual field tests under as many hunting conditions as possible. Each Phase requires different combinations of equipment.

Phase 1 – Five identical Cooper Phoenix rifles with Model 38 actions (one in each caliber)

All have 24” stainless steel Wilson barrels. Each rifle was produced with their very attractive composite varmint style stock. A second stock was also provided for each rifle. They are wooden laminated units produced in bench rest style. This allows the rifles to be used with standard bench rest front and rear rests for load accuracy testing.

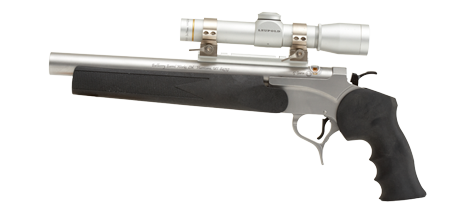

Phase 2 – Thompson / Center ENCORE w/ 5 barrels (one in each caliber)

All barrels are 12” long – 1” diameter stainless steel bull barrels. Each barrel has been equipped with a strain gauge epoxied over the center of the chamber.

Phase 3–Stolle Panda bench rest rifle w/ 5 Kreiger barrels (1 in each caliber)

All barrels are 24” long stainless steel. The action is pillar bedded rather than glued in to facilitate barrel changing and allow clearance for the mounting of strain gauges that are attached to the individual barrels. A custom bolt was manufactured by Kelbly’s to have the proper bolt face diameter. A major advantage of the Panda rifles is that once they are properly chambered, the barrels can be quickly changed knowing that the proper headspace will always be maintained. This rifle has the full bench rest treatment with a Jewel trigger set at 2 oz., and a 45 power Leupold competition scope. This combined with a J-J Industries front rest and Edgewood rear bag absolutely minimizes mechanical variables during load development. Now, if could only do something about wind and the shooter!